A tank roof with a weak roof to shell connection that fails more easily than the rest of the tank under excessive internal pressure.

Frangible roof storage tank.

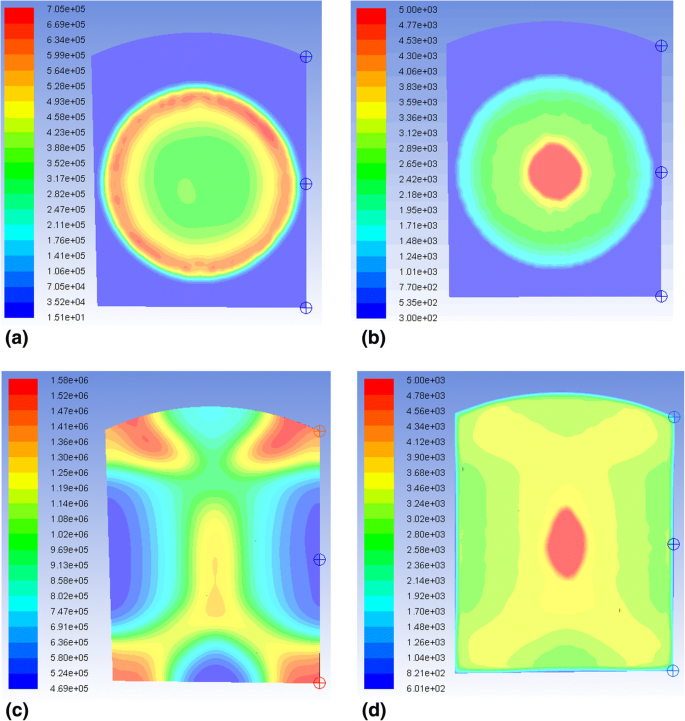

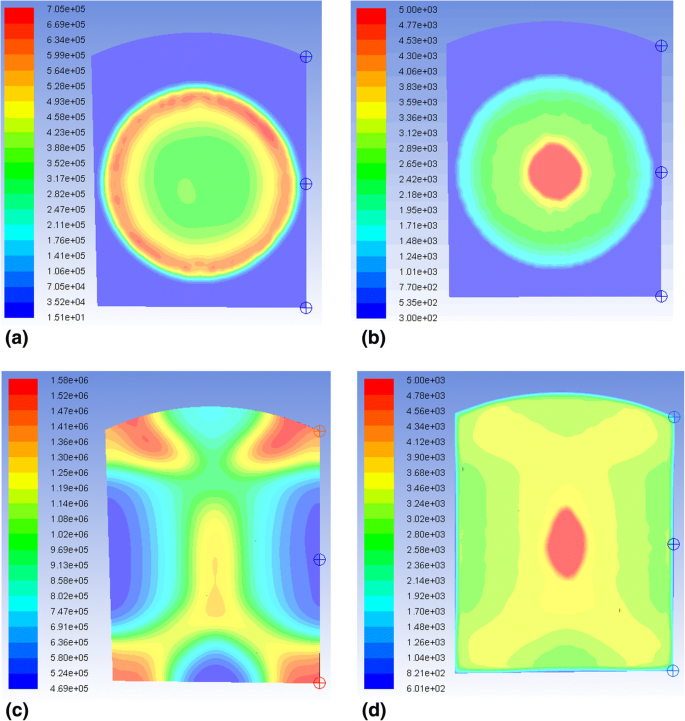

Referring now to fig.

Referring now to fig.

A vent that uses the weight of the pallet or cover to close.

The api 650.

1 there is generally indicated at 1 a conventional frangible roof joint for a storage tank 3 of relatively large diameter e g fifty feet 15 2m or more.

Api 650 is the standard governing welded tanks for oil storage.

This failure is intended to vent the tank and contain any remaining fluid.

Api 650 is widely used for tanks that are designed to internal pressures of 2 5 psi or less and store products such as crude oil gasoline chemicals and produced water.

This video documents the research and testing on frangible joint storage tanks performed at kansas state university and thunderhead engineering.

Such relatively weak roof to shell joints are known as frangible.

It dictates tank design fabrication welding inspection and erection requirements.

1 there is generally indicated at 1 a conventional frangible roof joint for a storage tank 3 of relatively large diameter e g fifty feet 15 2m or more.

The tank 3 comprises a cylindrical shell 5 having a rim at its upper edge formed by an angle 7 affixed to the outside of the shell.

Frangible roofs are normally specified as a means of providing emergency relief venting in the situation when a tank is engulfed in fire or the adjacent tank is on fire causing rapid vaporisation of the stored product such that the normal venting system cannot cope and the pressure in the tank rises to a point where the roof to shell joint fails.

Eemua 180 gives guidance to designers and users of such tanks on the practical steps that can be taken in design operation and maintenance to predispose the roof to shell joint to fail in preference to the shell to bottom joint thereby ensuring retention of the tank s contents.

In the event of over pressurization the frangible roof to shell joint is designed to fail before the tank shell or the shell to bottom joint.

The tank 3 comprises a cylindrical shell 5 having a rim at its upper edge formed by an angle 7 affixed to the outside of the shell.

The reasoning behind present api design formulas is reviewed.